- Cost-iron base

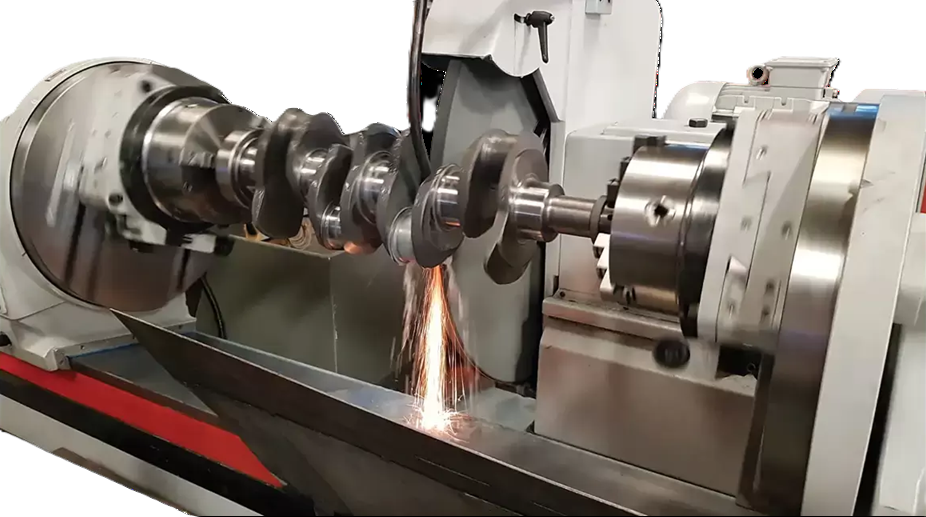

- Semi Automatic Grinding Mode/Reference Memory mode

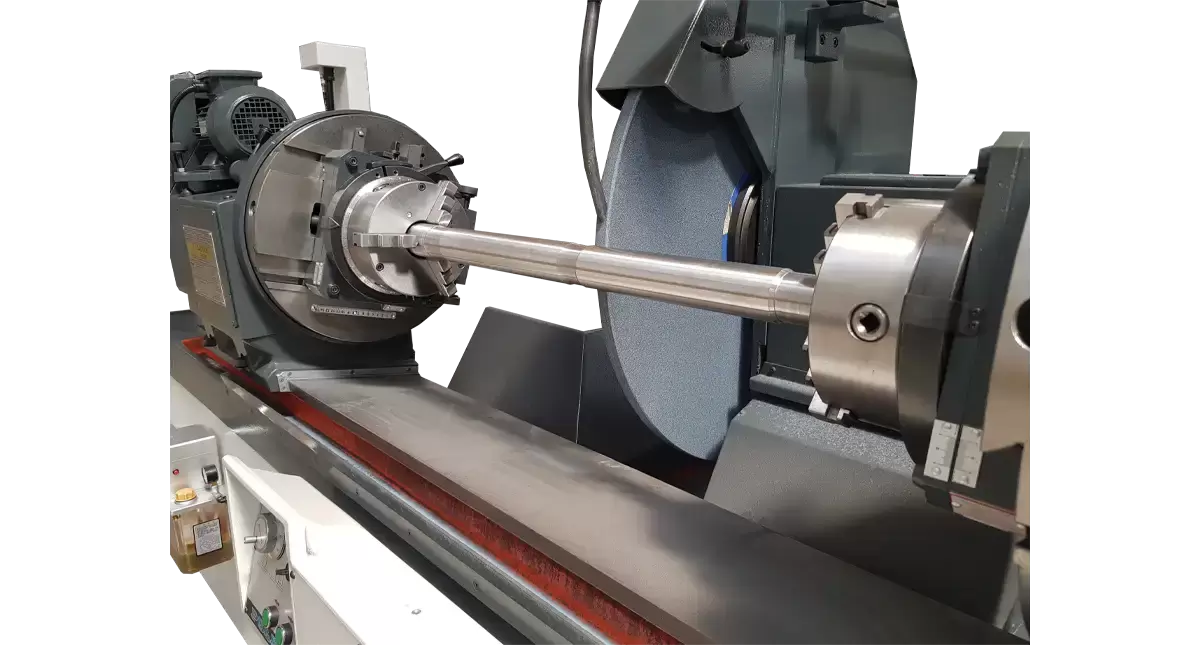

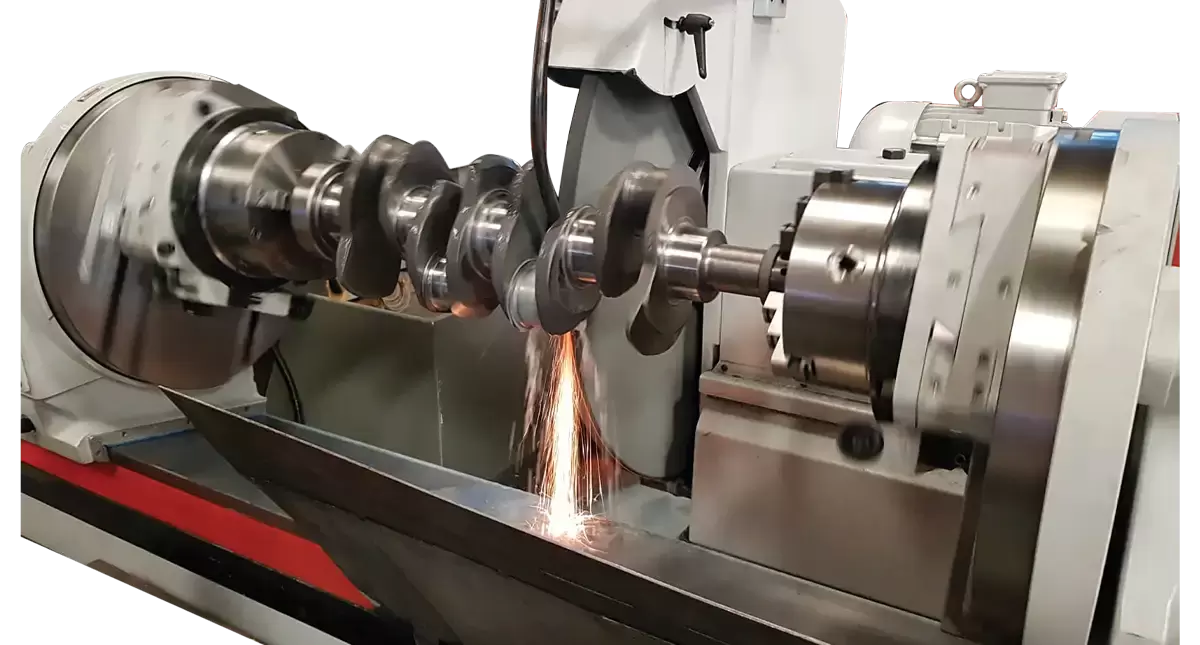

- Automatic Shaft/Spindle Grinding Process (Automatic Feeding)

- Ethernet and Remote connection system available Industry 4.0

- Servo Control Grinding Wheel(Y-Axis) and Table Movement(X-Axis)

- Wheelhead forward,backward movemetns(Speed Adj.)

- Ball Screw system for (X-Y axis)

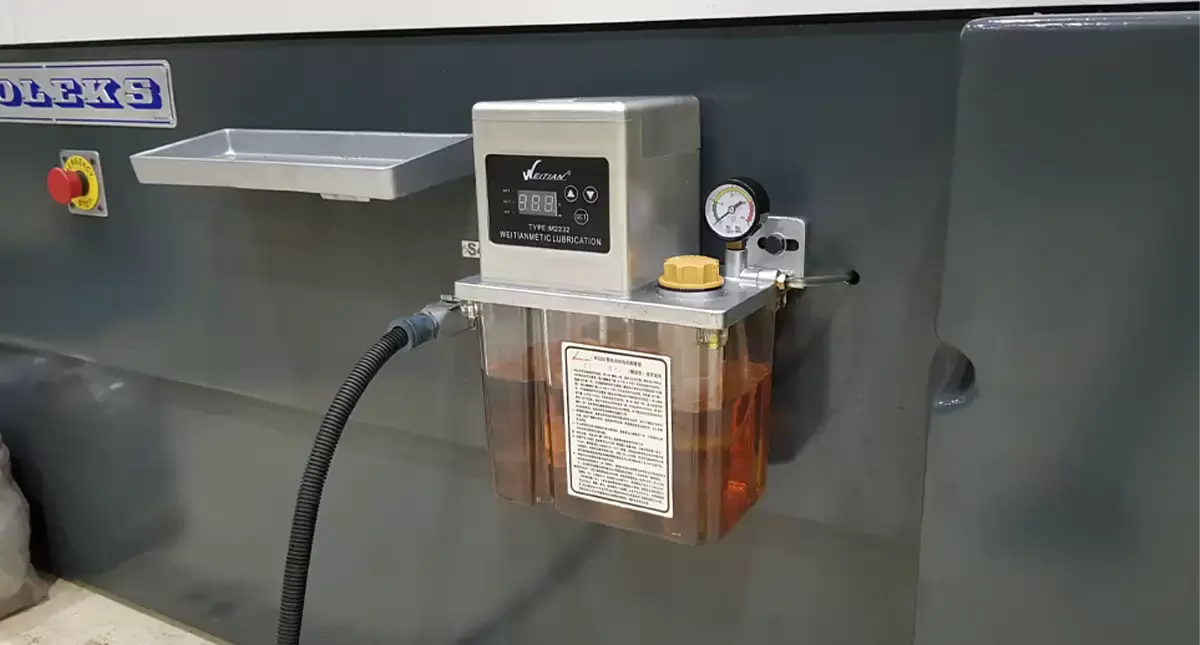

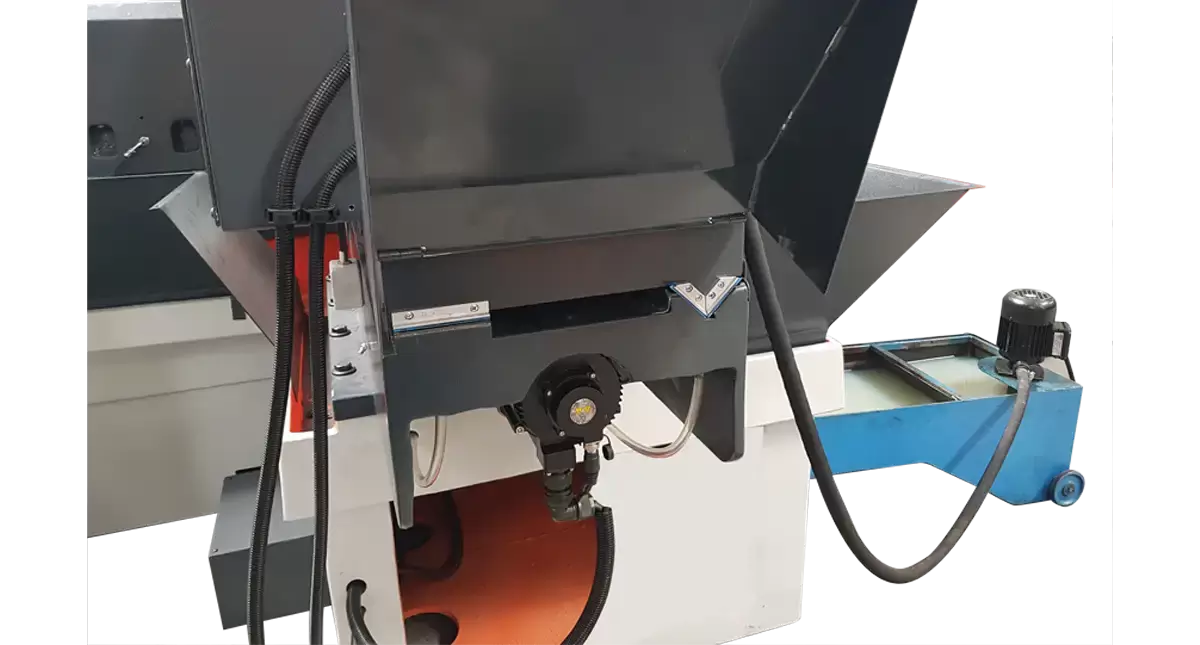

- Automatic lubrication system (All slides and ball screws)

- Cooler system for main wheel spindle(Optional)

- Speed Adjustable Electronic Handwheel for (X-Y axis)

- Electronic hand-wheel for precision feeds movement(0.005)

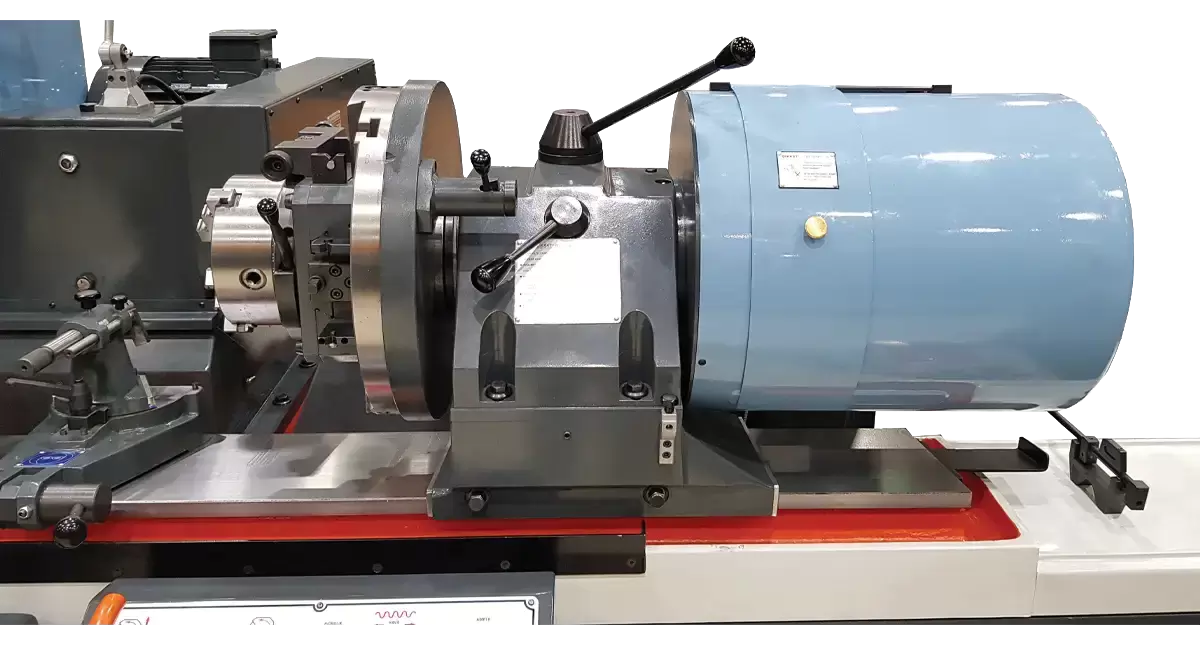

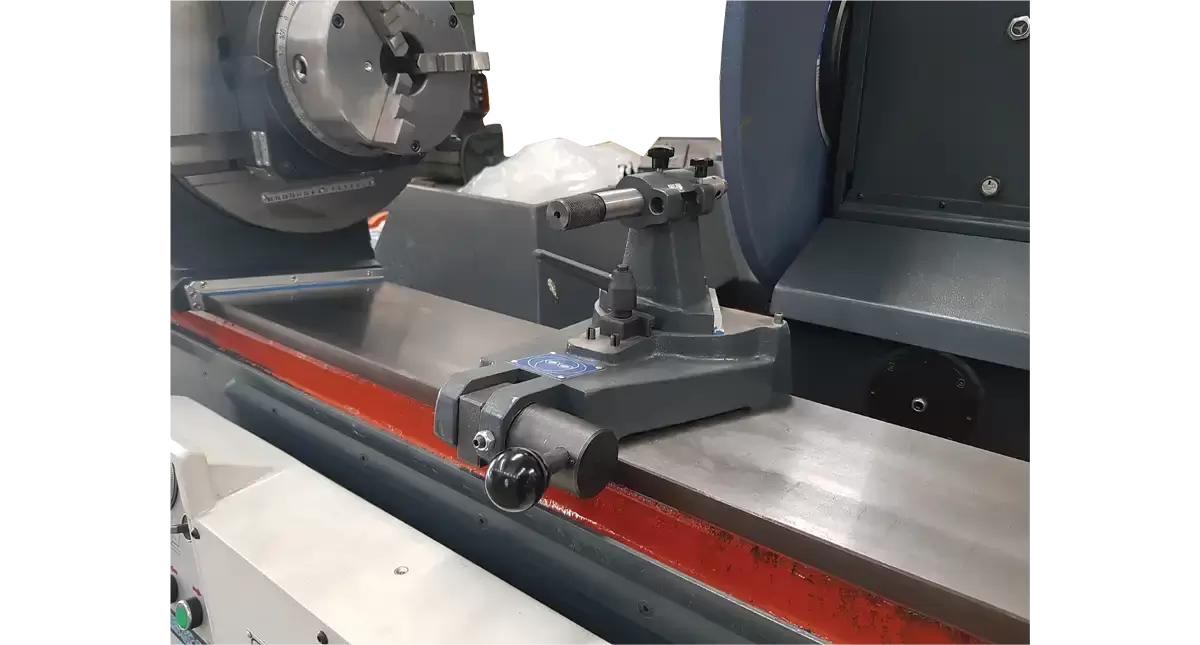

- Headstock and tailstock displacement on air cushion

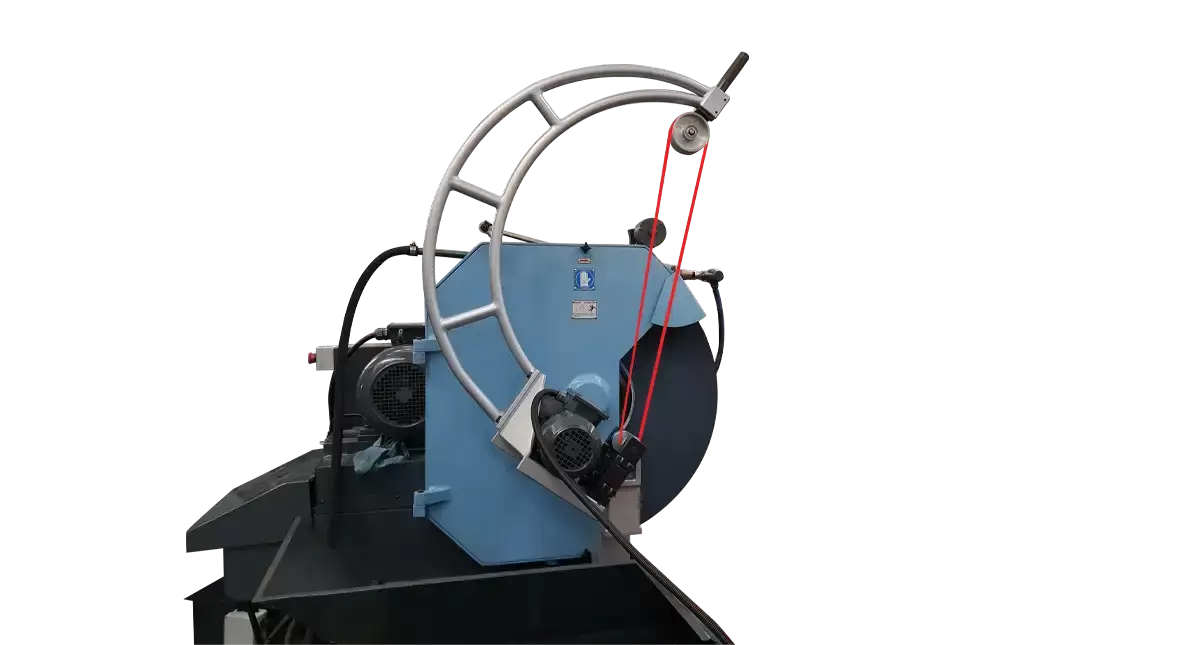

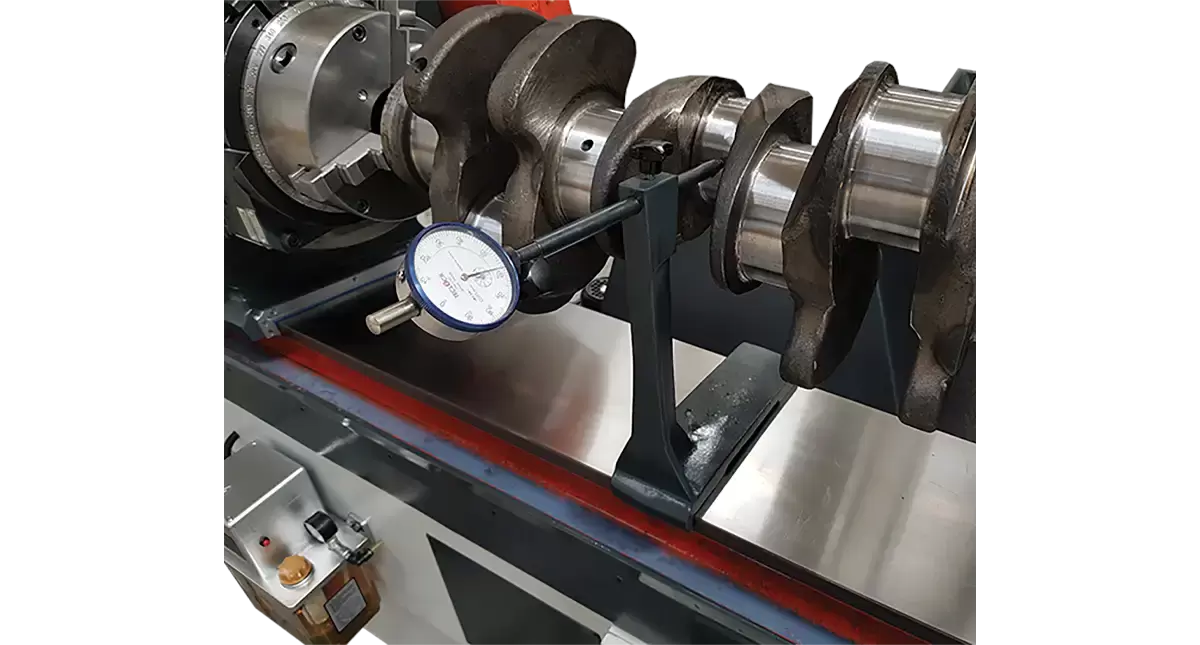

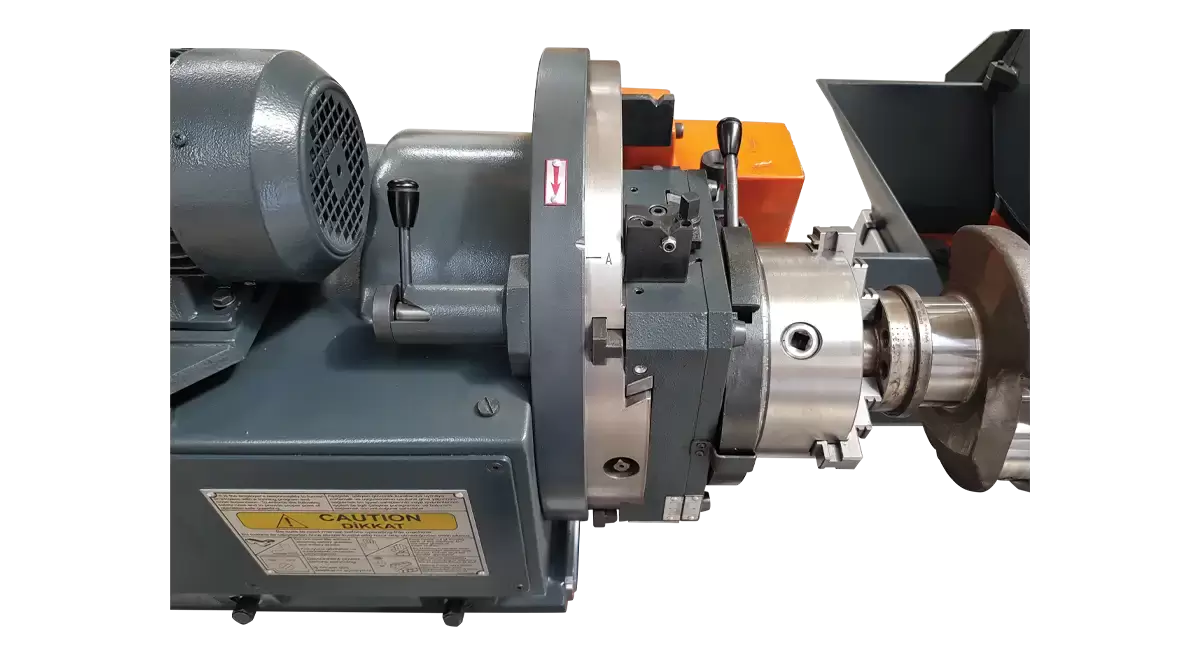

- Electronic speed adjustable crank rotation motor

- Fast speed powered table traverse (X axis)

- Incremental electronic measuring device (X-Y axis)

- Movable Work lighting lamp

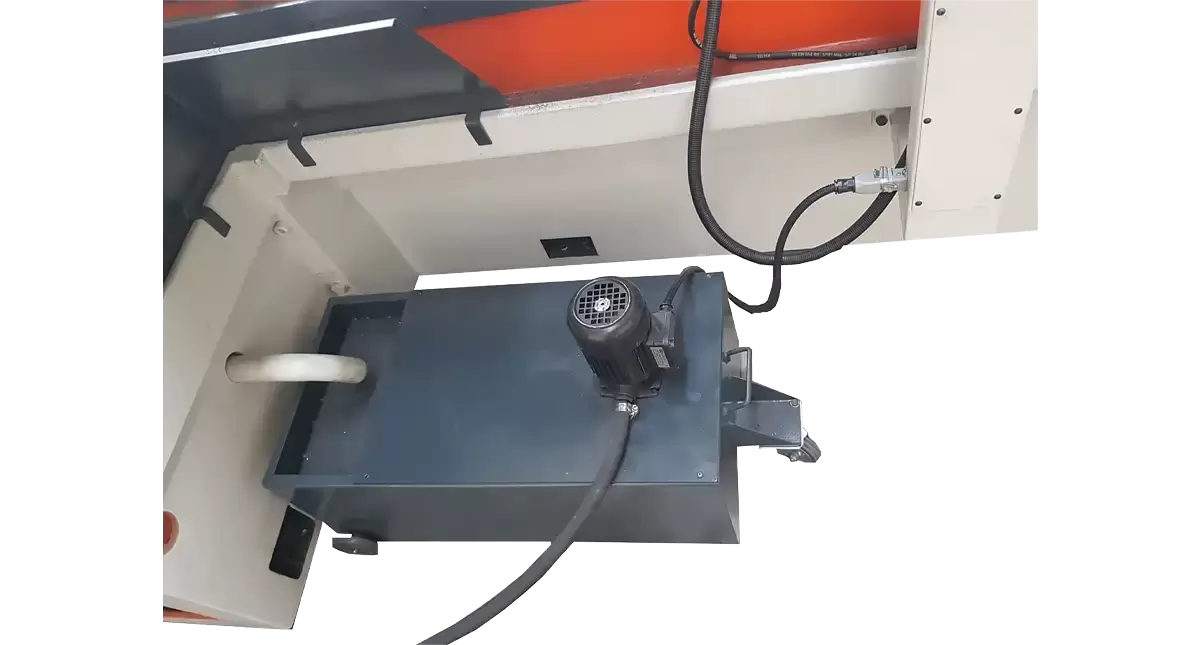

- Cooling unit with fabric filter System

- Magnetic Water Separator (Optional tool)

- Moveable centering system (Optional tool)

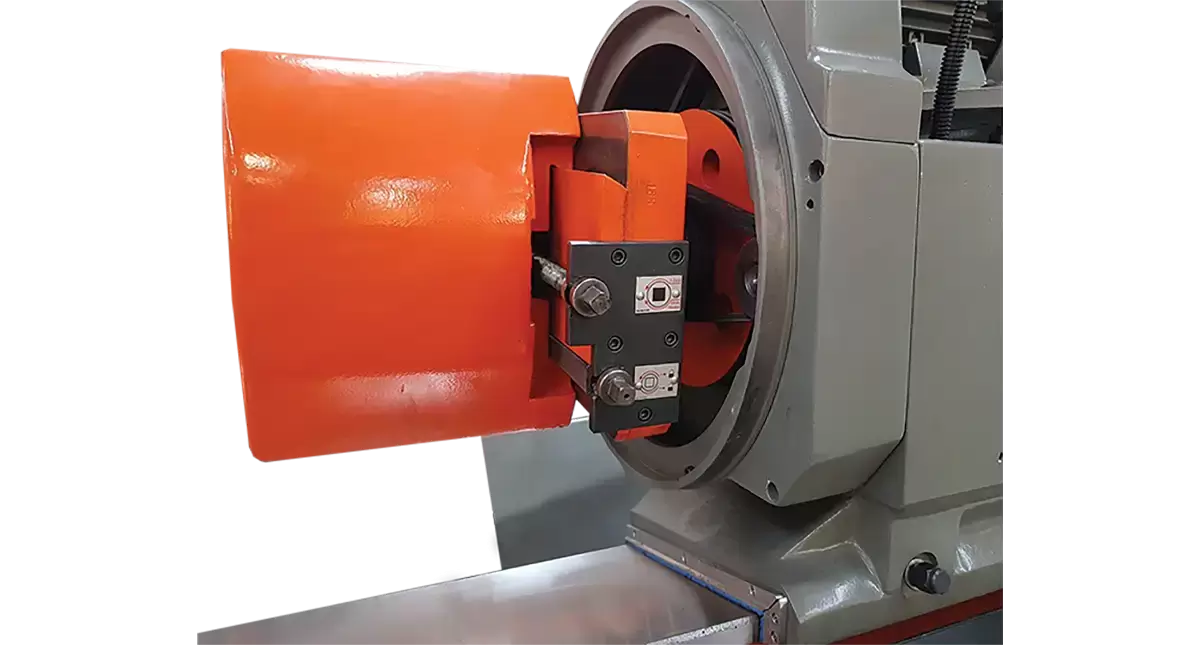

- Wheel head movement secure system

- (LCD)Touch Screen and NC-Software system

- Electric panel inside lighting lamp

- 220V Electric power plug on control panel for foreign uses

| Serial No | Standard / Extra Equipments | KT 1800 | |

| Standard | Extra | ||

| 02100 | Service Tool box (Kit) | 1 | |

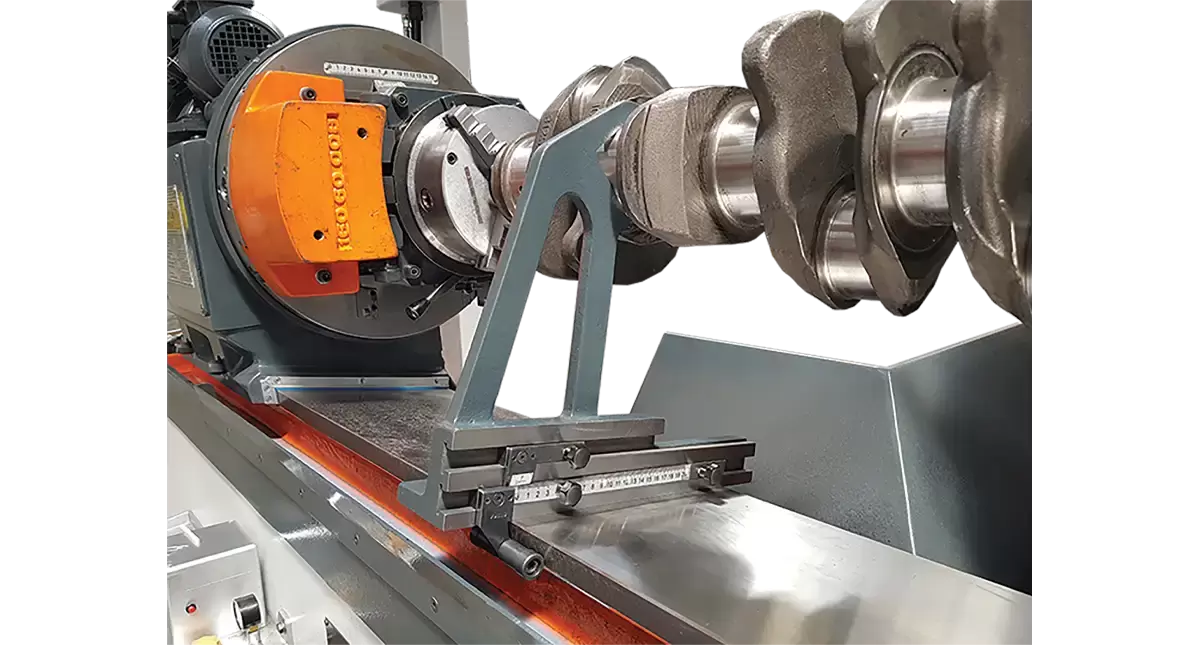

| 02101 | Stroke or Center Position Checking Apparatus | 1 | |

| 02102 | Device for taking the crank throw | 1 | |

| 02103 | Centering rod mounted onto the check square | 1 | |

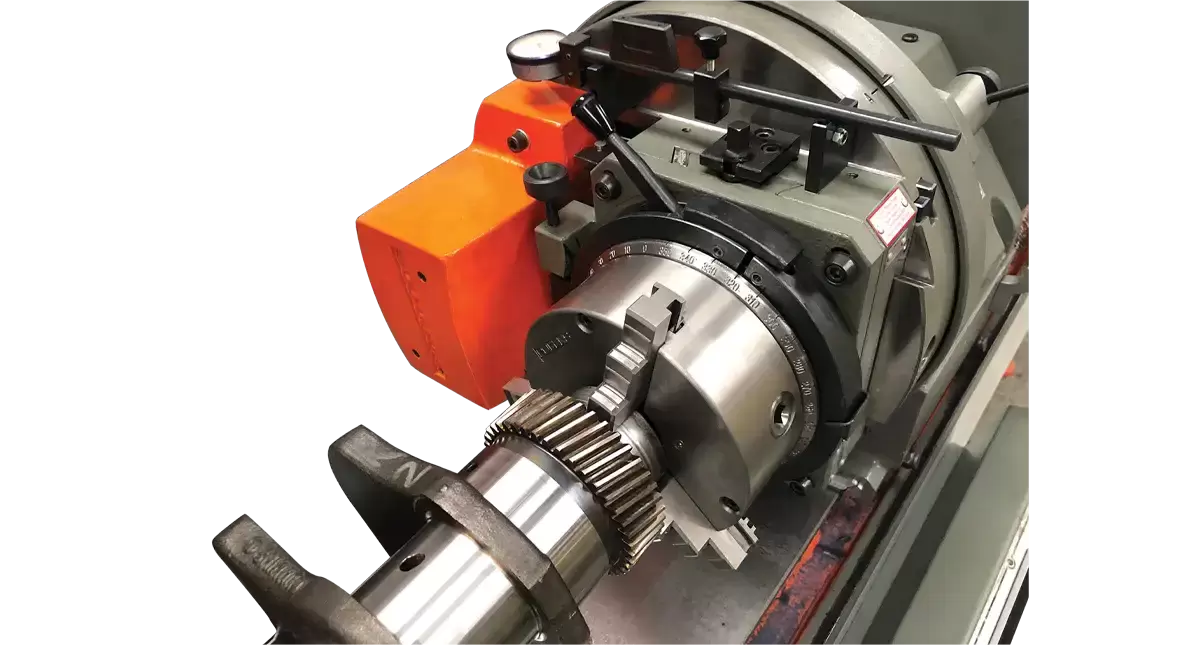

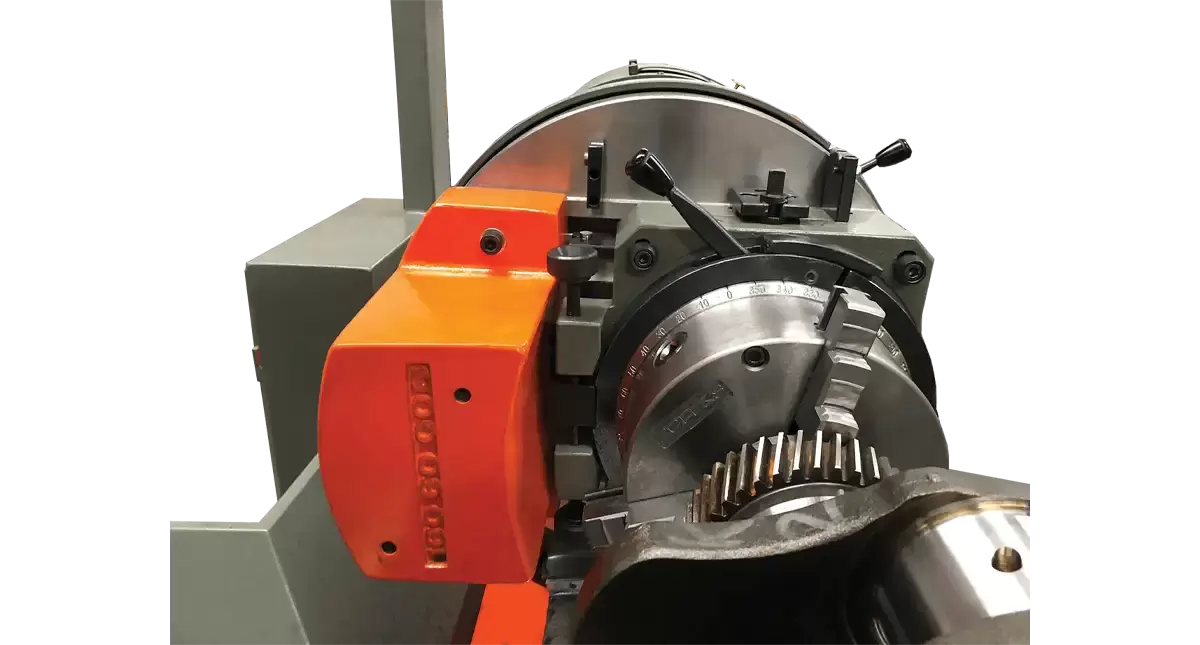

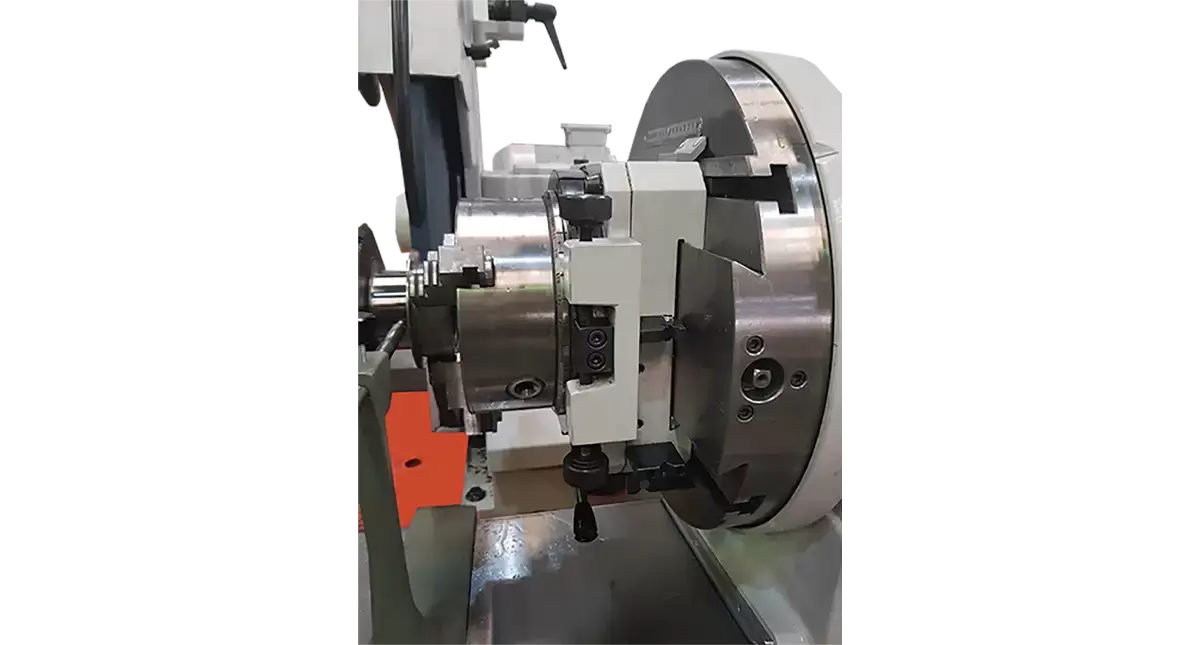

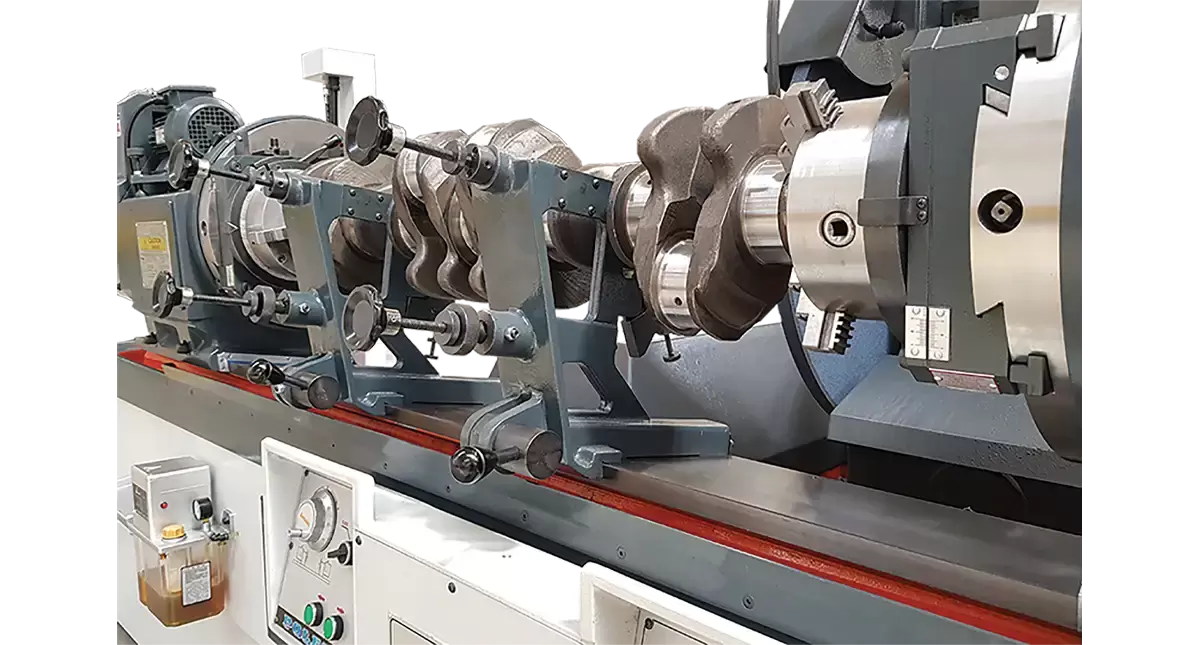

| 02104 | Self Centering Chucks | 2 | |

| 02105 | Wheel flange disassembly kit | 1 | |

| 02106 | Narrow Steady Rest with built-in centering fixture | 1 | |

| 02107 | Pair of flanges for grinding wheel | 1 | |

| 02108 | Grinding wheel face and radius dresser(cutter diamond exluded) | 1 | |

| 02109 | Cooling system tank | 1 | |

| 02110 | Speed adj.Electronic handwheel(X-Y axis) | 1 | |

| 02111 | Pneumatic system | 1 | |

| 02112 | Fixing Locks | 2 | |

| 02113 | Precision incremental in-feed(elc.handwheel) | 1 | |

| 02114 | Electronic Powered Fast Table Traverse | 1 | |

| 02115 | Digital Meausuring Device(X-Y axis) | 1 | |

| EA0024 | Crankshaft superfinishing through device | Extra | |

| TÇK0023 | Grinding wheel | 1 | |

| 02116 | Work lighting lamp | 1 | |

| 02117 | Grinding wheel balancing arbor | 1 | |

| 02118 | Counter Weight | Extra | |

| 02119 | Continuous measurement attachment | Extra | |

| 02120 | Cathtplate | Extra | |

| 02121 | Drivers with locking pins | Extra | |

| 02122 | Conic Centers | Extra | |

| 02123 | Safety flop and switch | Extra | |

| 02124 | Grease lubrication pump | 1 | |

| 02125 | Automatic lubrication system | 1 | |

| 02126 | Magnetic cooling water seperator | ||

| 02127 | (Fixed)Crankshaft superfinishing through device | Extra | |

| Technical Specifications | KT 1800 | |

| Height of center over table | mm | 300 |

| Max.Distance between centers(2 executions) | mm | 1800 |

| Max.Swing over Table | mm | 600 |

| Max.Head offset | mm | 150 |

| Max. Diameter ground with full-size wheel | mm | 500 |

| Max. Mass admitted between centers | kg | 800 |

| Max.Weight admitted (with steady rests) | kg | 2000 |

| Self-centering chuck diameter | mm | 200 |

| Table Micrometer feed of Elc.Handwheel | mm | 0.005 |

| Table Automatic quik movement | mm/min | 10000 |

| Workpiece rotation speed (stepless) | r.p.m | 0 - 100 |

| Grinding wheel diameter | mm | 815 |

| Max. Grinding wheel thickness | mm | 60 |

| Min. Grinding wheel thickness | mm | 16 |

| Air pressure for heads displacement | bar | 6 |

| Wheelhead fast traverse speed | mm/min | 200 |

| Wheelhead Micrometer feed of Elc.Handwheel (min) | mm | 0.005 |

| Grinding wheel motor power | kw | 5.5 |

| Workhead motor power | kw | 0.75 |

| Wheel head (forward-backward) movements motor power | kw | 1.5 (AC Servo) |

| Table control motor power | kw | 3.8 (AC Servo) |

| Cooling unit motor power | kw | 0.37 |

| Work length of machine | mm | 6050 |

| Length of machine | mm | 4450 |

| Width of machine | mm | 2040 |

| Height of machine | mm | 1600 |

| Weight of machine | kg | 4750 |