- Cast- iron base

- (LCD)Touch Screen and CNC-Control unit

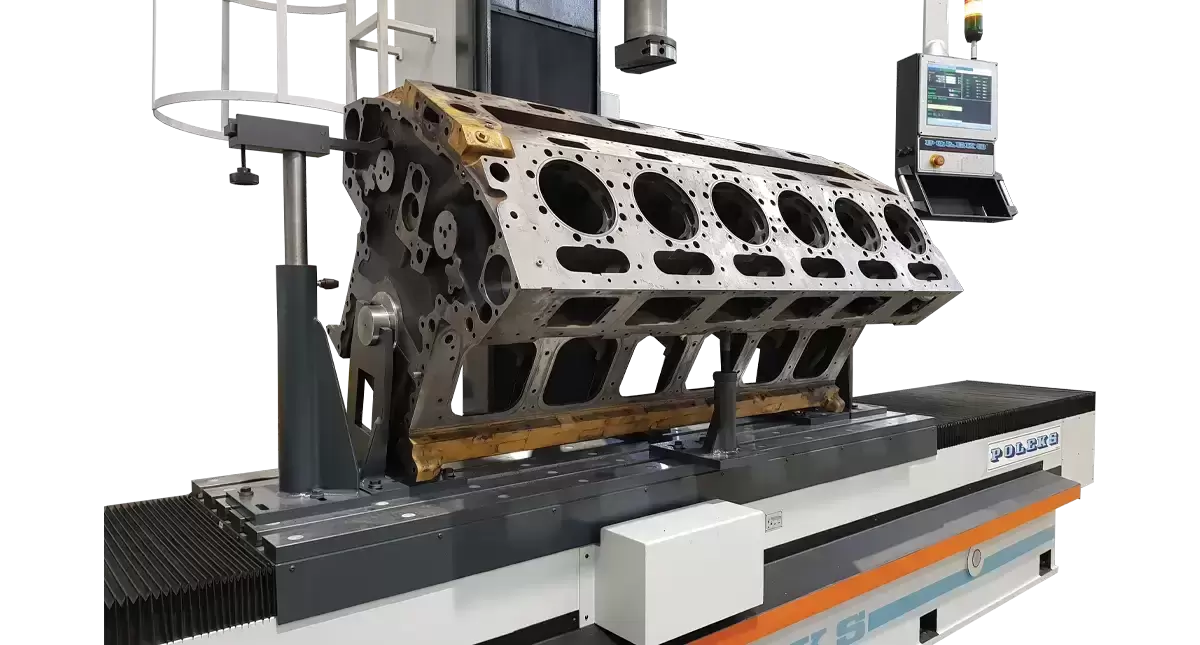

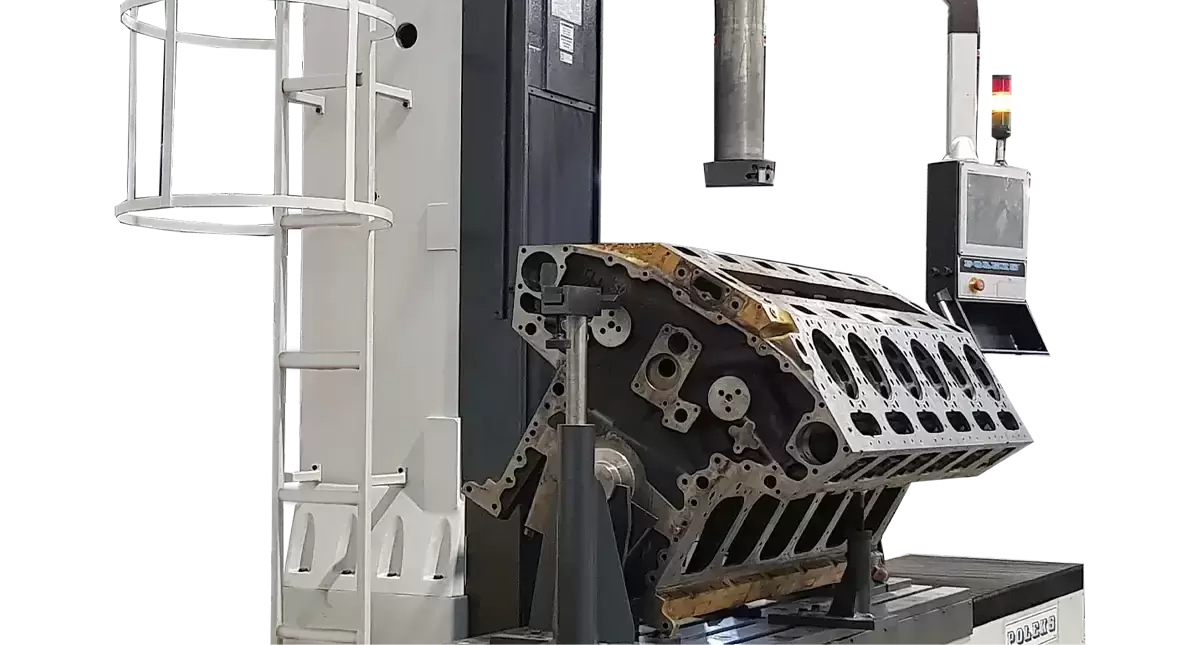

- Automatic CNC – Cylinder boring process

- Interplation system while cylinder boring process running (Optional)

- `X-Y-Z’ Axis AC/Servo motor control

- Electronic Hand Wheel for X-Y-Z axis.(Speed Adjustable)

- Incremental electronic measuring device (X,Y,Z axis)

- Simulation of the boring and milling process (Optional)

- Movable Boring head changer robot (Optional)

- Spindle Head Up and Down movements with speed adjustable

- Electronic speed adjustable Spindle rotation (Elc.Hand Wheel Control)

- Speed adjustable table for surfacing process

- Movable work lighting (LED)lamp

- Prepared system chip breakers (cutting tools)

- Column curtain for secure the slides

- Column(Z-axis) ‘V’ type slide system

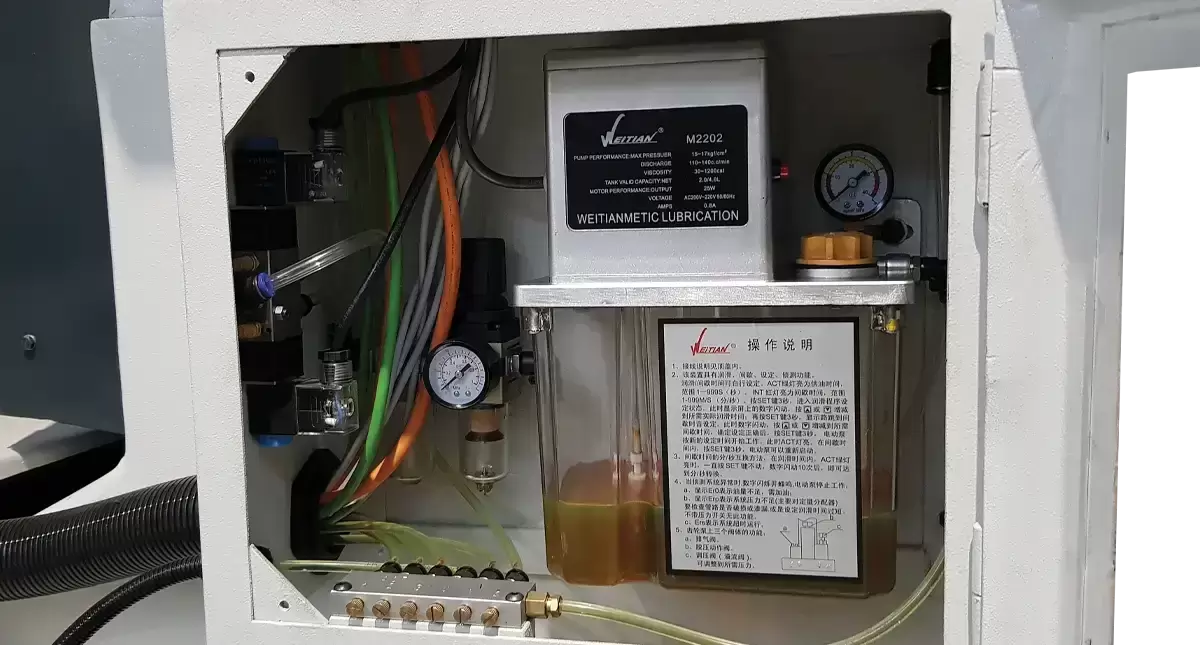

- Table slides (X-Y axis)‘Linear Guides ‘ with automatic lubrication system

- Electric panel inside lighting lamp

- Boring head with marble system

- Spindle Head down and up movements with ball screw and automatic lubrication.

- Ball screw system for table forward-backward and right-left movements with automatic lubrication. (X-Y axis)

- Time setting Automatic Lubrication System

- Electronic hand wheel control and movements for X,Y,Z axis

- Ethernet and Remote connection system available Industry 4.0

- Colum sevice stairs

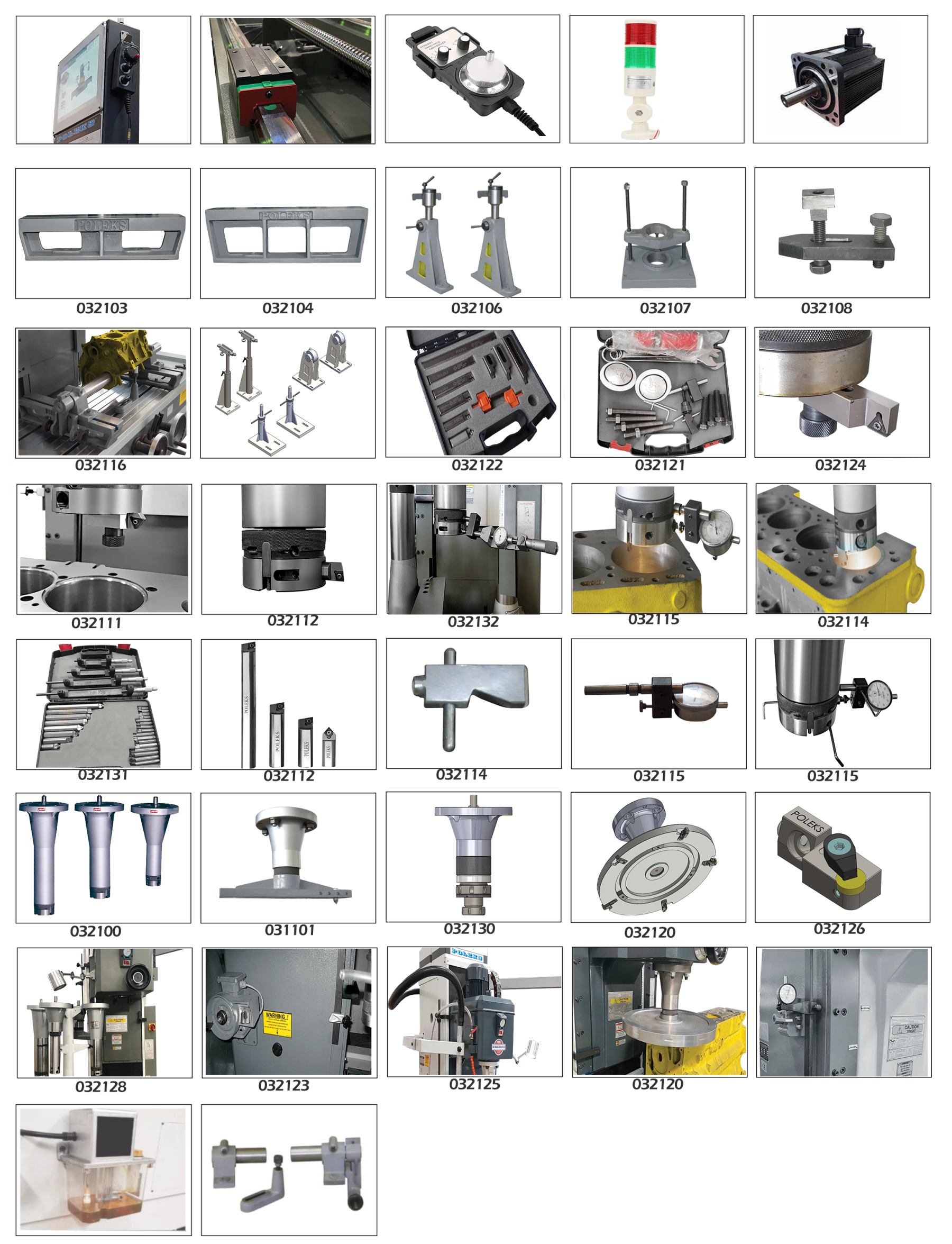

| Serial Number | Standard / Extra Equipments | Standard | Extra |

| 032100 | Boring head | 3 | |

| 032101 | Surfacing head | 1 | |

| 032103 | Pair of parallels, supports 100 mm (small) | 2 | |

| 032104 | Pair of parallels, supports 200 mm (big) | 2 | |

| 032106 | Pair of quick setting up fixture | Extra | |

| 032107 | Setting-up fixture for finned engine blocks | 1 | |

| 032108 | Clamping engine block | 4 | |

| 032109 | Setting screws and nuts | 10 | |

| 032110 | Automatic lubrication system | 2 | |

| 032111 | Chamfering tool | 3 | |

| 032112 | Chip breaker | 5 | |

| 032113 | Surface Milling Chip breaker | 1 | |

| 032114 | Cylinder centering device | 1 | |

| 032115 | Tools setting device without dial gauge 1 | 1 | |

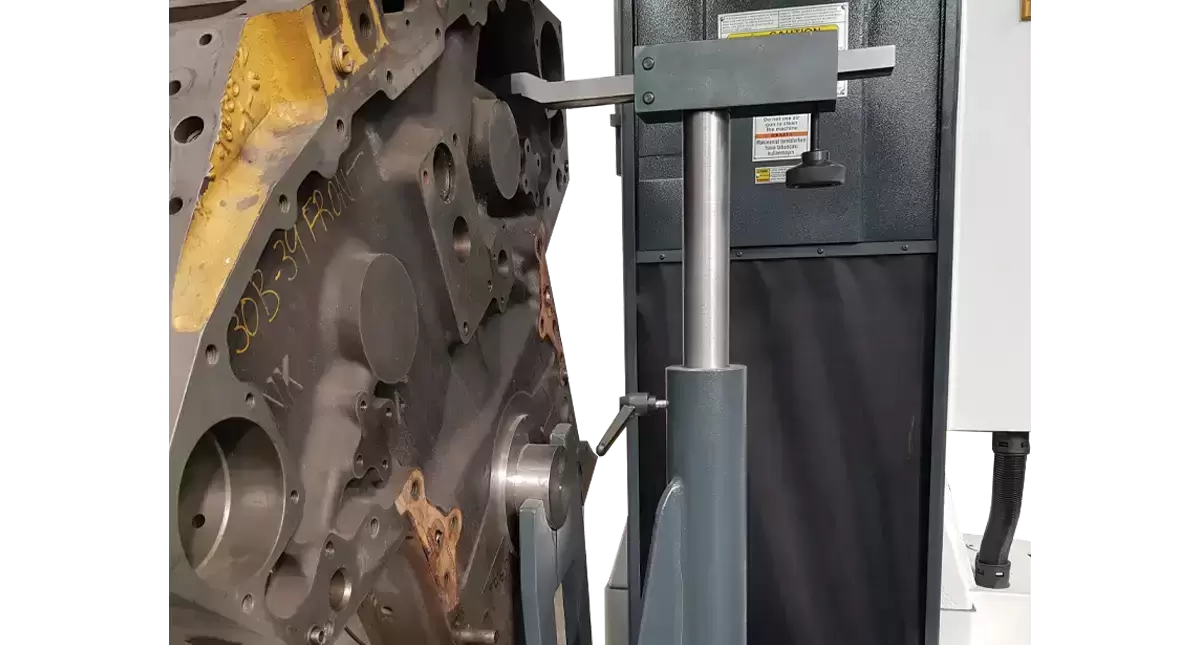

| 032116 | Universal Fulcrum lever and V block apparatus(Type 2) | 1 | |

| 032117 | Boring heads changer robot | Extra | |

| 032119 | Mliilng head safeguard | Extra | |

| 032120 | Circular multiple surface milling head | Extra | |

| 032121 | Tool Box ( 2pcs wrench - oil pump -assembly tools screws and nuts ) | 1 | |

| 032122 | Tool Box for chip breakers and tool holders | 1 | |

| 032123 | Diamond(tool) dresser ( to sharpen the chip braker ) | Extra | |

| 032124 | Boring tool component with a dead-end hole tool | Extra | |

| 032125 | Movable shavings vacum device | Extra | |

| 032126 | Tool Holder (for Cbn/Pcd) | Extra | |

| 032127 | V-type engine fixing apparatus(Type 1) | Extra | |

| 032128 | Heavy-Duty V-type engine apparatus(Type 3) | Extra | |

| 032129 | Special heavy-duty boring head | Extra | |

| 032130 | Special boring head for suitable morse system | Extra | |

| 032131 | Micrometer type tooling system | Extra | |

| 032132 | Feed dial guage micrometer | Extra |

| Technicial Specifications | RM 3100 | |

| Max.Center diameter | mm | 400 |

| min. Grinding diameter | mm | 65 |

| Max. milling width | mm | 450 |

| Distance between spindle axis and slide | mm | 625 |

| Max. grinding stroke (without head) | mm | 2420 |

| table working surface | mm | 3100x705 |

| Max. Longitudinal movement of the table | mm | 3100 |

| Max. Transverse movement of the table | mm | 200 |

| Rectifier head rotation speed (speed adjustable) | d/rpm | 0-700 |

| Automatic Movement of Grinding Head (up and down)-(speed adjustable) | mm/min | 0-700 |

| Fast movement of the grinding head (down, up) | mm/min | 6000 |

| Table rapid traverse speed | mm/min | 10000 |

| Table automatic advance (stepless) | mm/sec | 0-700 |

| electrical system | V | 380 - 24 |

| spindle motor | Kw | 4 |

| Transmission motion motor (up - down) | Kw | 1,1 |

| Table automatic advance motor | Kw | 2.2 |

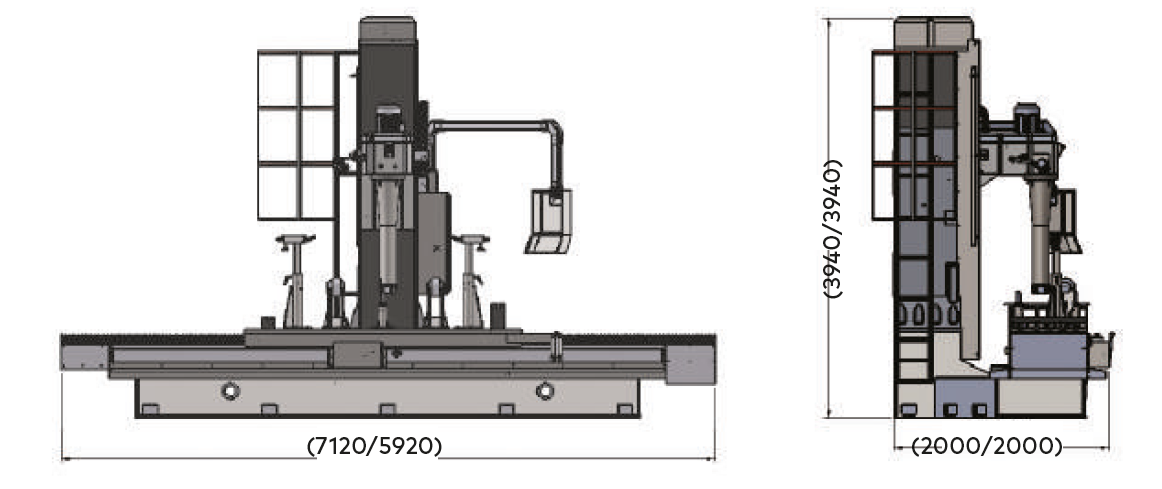

| Machine working length | mm | 9700 |

| Machine size | mm | 7120 |

| Machine width | mm | 2000 |

| Machine height | mm | 3940 |

| Machine weight | kg | 9000 |